Among the available high performance building systems on the market today, Insulated Concrete Forms (ICFs) are rapidly leading the way in high performance building systems as the fastest growing alternative for above grade walls. According to the NAHB Research Center, the use of ICFs in the construction of new single family homes grew 750% between 2002 and 2010– representing 12,000 new homes built that year.

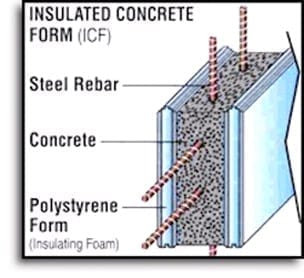

ICFs are molded from expanded or extruded polystyrene into lightweight, interlocking foam blocks, which then serve as permanent forms for poured concrete walls. This process eliminates the need for insulation on either side of the wall to achieve optimal thermal values. Some ICF structures go a step further with the inclusion of integral metal inserts that strengthen and stabilize walls. These inserts protrude though the blocks to provide nailing strips for interior and exterior finishes like drywall and even stucco.

Once completed, ICF structures are greatly resistant to fire and high winds, promote energy-efficiency and noise reduction, and are highly durable. In recent months, the TightLines team has seen an increased number of requests for design services accommodating this building system, specifically in the international market as well as hurricane and tornado prone areas in the US.

According to research conducted by Building Works, Inc., houses with ICF exterior walls require an estimated 44% less energy to heat and 32% less energy to cool than comparable wood insulating frame houses. This performance is largely attributable to the polystyrene foam on the interior and exterior of ICF walls, which range from R-17 to R-26 compared to wood framed houses with R-values between R-9 and R-15.

From an architectural perspective, ICFs provide benefits as well. ICF homes can be designed to meet non-combustible construction qualifications. ICFs can be easily cut to fit in window rough openings with reinforced rebar. Additionally, home construction techniques contribute to a number of green certification criteria (such as the LEED for Homes Rating System) due to air tight construction methods, minimal waste, and durable building materials and performance.

———————————

TightLines is pleased to offer ICF compatible designs. Construction documents can be created for a number of applications including single-family, multi-unit residential, and assisted living facilities. TightLines partners with a number of ICF manufactures including Amvic. Headquartered in Toronto, Canada, Amvic has aligned with several factories in the US (including Charlotte, NC) to produce high quality, energy-efficient ICF products. Offering materials with superior strength and ease of installation, Amvic is quickly becoming a world renowned industry leader in the manufacturing of ICF materials.